Quote:

Ya....OK... Try my little site glass test on 1 of your perfect engines and see what happens.

What’s your problem? I stated a fact and you take it personal? A correctly functioning Crank case ventialtion system should never cause an oil consumption problem, the problem lies somewhere else. A good engine builder asks himself if he’s fixing the symptom or the problem?

Here’s some helpful information on PCV and CCV systems.

PCV Systems

During the last stages of combustion in an engine’s cylinders,

some unburned fuel and products of combustion

leak past the piston rings and move into the crankcase.

This leakage is called blowby. Blowby must be removed

from the engine before it condenses in the crankcase and

reacts with the oil to form sludge. Sludge, if allowed to

circulate with engine oil, corrodes and accelerates wear

of pistons, piston rings, valves, bearings, and other internal

working parts of the engine.

Blowby gases must also be removed from the crankcase

to prevent premature oil leaks. Because these gases

enter the crankcase by the pressure formed during combustion,

they pressurize the crankcase. The gases exert

pressure on the oil pan gasket and crankshaft seals. If the

pressure is not relieved, oil is eventually forced out of

these seals.

Because the air/fuel mixture in an engine never completely

burns, blowby also carries some unburned fuel

into the crankcase. If it is not removed, the unburned fuel

dilutes the engine’s oil. When oil is diluted, it does not lubricate

the engine properly, which causes excessive wear.

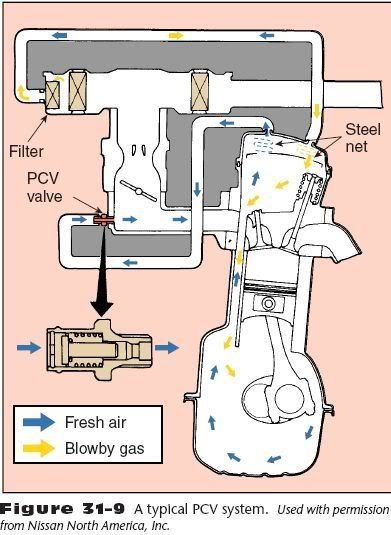

Operation Combustion gases that enter the crankcase

are removed by a positive crankcase ventilation (PCV)

system, which uses engine vacuum to draw fresh air

through the crankcase. This fresh air enters through the

air filter or through a separate PCV breather filter located

on the inside of the air filter housing.

When the engine is running, intake manifold vacuum

is supplied to the PCV valve. This vacuum moves air

through the clean air hose into the rocker arm cover. From

this location, air flows through cylinder head openings into

the crankcase, where it mixes with blowby gases.

The mixture of blowby gases and air flows up through

cylinder head openings to the PCV valve. Intake manifold

vacuum moves the blowby gas mixture through the

PCV valve into the intake manifold (Figure 31–9).

The blowby gases mix with the intake charge and enter the

combustion chambers, where they are burned.

The PCV system prevents the emission of blowby

gases from the engine crankcase to the atmosphere and

scavenges the crankcase for vapors that could dilute the

oil and cause it to deteriorate or that could build undesirable

pressure in the crankcase. An inoperative PCV

system could shorten the life of the engine by allowing

harmful blowby gases to remain in the engine, causing

corrosion and accelerating wear.

PCV Valve The PCV valve (Figure 31–10)

is usually mounted in a rubber grommet in one of the valve covers.

A hose is connected from the PCV valve to the intake

manifold. A clean air hose is connected from the air

cleaner to the opposite rocker arm cover. A filter is positioned

in the air cleaner end of the clean air hose. On some

systems, the PCV valve is mounted in a vent module, and

the clean air filter is located in this module.

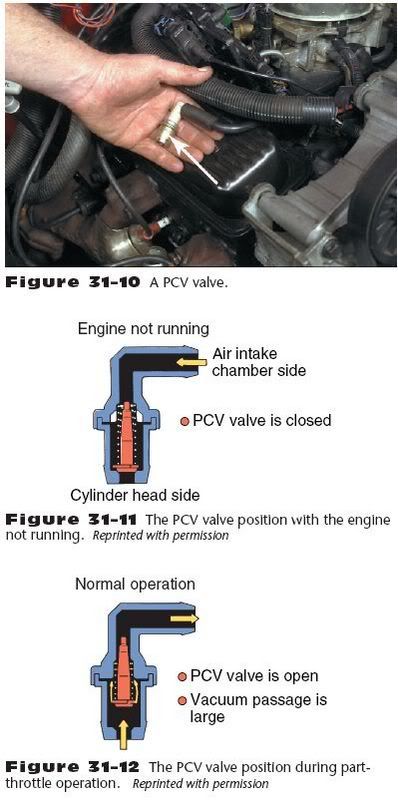

A PCV valve contains a tapered valve. When the engine

is not running, a spring keeps the tapered valve

seated against the valve housing (Figure 31–11).

During idle or deceleration, the high intake manifold vacuum

moves the tapered valve upward against the spring tension.

Under this condition, the blowby gases flow through

a small opening in the valve. Since the engine is not under

heavy load, the amount of blowby gas is minimal and the

small PCV valve opening is all that is needed to move the

blowby gases out of the crankcase.

Manifold vacuum drops off during part-throttle operation.

As the vacuum signal to the PCV valve decreases,

a spring moves the tapered valve downward to increase

the opening (Figure 31–12). Since engine load is higher

at part-throttle operation than at idle, blowby gases are

increased. The larger opening allows all the blowby gases

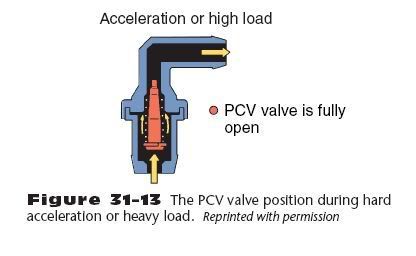

to be drawn into the intake manifold. When the engine is operating under heavy load with a wide throttle opening, the decrease in intake manifold vacuum allows the spring to move the tapered valve further downward in the PCV valve

(Figure 31–13),

providing a larger opening through the valve. Since higher

engine load results in more blowby gases, the larger PCV

valve opening is necessary to allow these gases to flow

through the valve into the intake manifold.

When worn rings or scored cylinders allow excessive

blowby gases to enter the crankcase, the PCV valve opening

may not be large enough to allow these gases to flow

into the intake manifold. Under this condition, the

blowby gases create a pressure in the crankcase, and some

of these gases are forced through the clean air hose and

filter into the air cleaner. When this action occurs, there

is oil in the PCV filter and air cleaner. This same action

occurs if the PCV valve is restricted or plugged.

If the PCV valve sticks in the wide-open position, excessive

airflow through the valve causes rough idle operation.

If a backfire occurs in the intake manifold, the

tapered valve is seated in the PCV valve as if the engine

were not running. This action prevents the backfire from

entering the engine, where it could cause an explosion.

Fixed Orifice Tube PCV System Some engines are

equipped with a PCV system that does not use a PCV

valve. Instead, the blowby gases are routed into the intake

manifold through a fixed orifice tube.

The system works the same as if it had a valve,

except that the system is regulated only by the vacuum

on the orifice. The size of the orifice limits the amount of

blowby flow into the intake. The engine’s air/fuel system

is calibrated for this calibrated air leak. Since the action

of the PCV allows unmetered air into the intake, the

air/fuel system must be set for this amount of extra air.

PCV SYSTEM DIAGNOSIS

AND SERVICE

No adjustments can be made to the PCV system. Service

of the system involves a careful inspection, operation, and

replacement of faulty parts. Some engines use a fixed orifice

tube in place of a valve. These should be cleaned periodically

with a pipe cleaner soaked in carburetor cleaner.

Although there is no PCV valve, this type of system is diagnosed

in the same way as those systems with a valve.

When replacing a PCV valve, match the part number on

the valve with the vehicle maker’s specifications for the

proper valve. If the valve cannot be identified, refer to the

part number listed in the manufacturer’s service manual.

If the PCV valve is stuck in the open position, excessive

air flow through the valve causes a lean air/fuel ratio

and possible rough idle operation or engine stalling.

When the PCV valve or hose is restricted, excessive

crankcase pressure forces blowby gases through the clean

air hose and filter into the air cleaner. Worn rings or cylinders

cause excessive blowby gases and increased crankcase

pressure, which forces blowby gases through the

clean air hose and filter into the air cleaner. A restricted

PCV valve or hose may result in the accumulation of

moisture and sludge in the engine and engine oil.

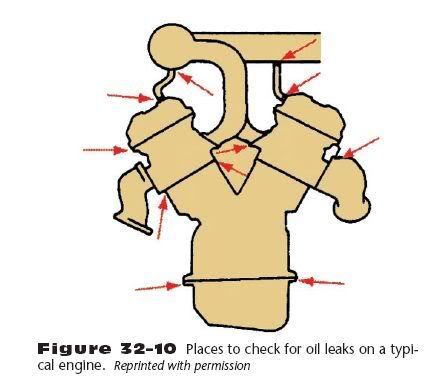

Leaks at engine gaskets, such as rocker arm cover or

crankcase gaskets, will result in oil leaks and the escape

of blowby gases into the atmosphere. However, the PCV

system also draws unfiltered air through these leaks into the engine.

This action could result in wear of engine components,

especially when the vehicle is operating in dusty

conditions. Check all the engine gaskets for signs of oil

leaks (Figure 32–10).

Be sure the oil filler cap fits and

seals properly.

The first step of PCV servicing is a visual inspection.

The PCV valve can be located in several places. The most

common location is in a rubber grommet in the valve

cover. It can be installed in the middle of the hose connections,

as well as installed directly in the intake manifold.

Once the PCV valve is located, make sure all the PCV

system hoses are properly connected and that they have

no breaks or cracks. Remove the air cleaner and inspect

the air and crankcase filters. Crankcase blowby can clog

these with oil. Clean or replace such filters. Oil in the air

cleaner assembly indicates that the PCV valve or hoses

are plugged. Make sure you check these and replace the

valve and clean the hoses and air cleaner assembly. When

the PCV valve and hose are in satisfactory condition and

there is oil in the air cleaner assembly, perform a cylinder

compression test to check for worn cylinders and piston

rings.

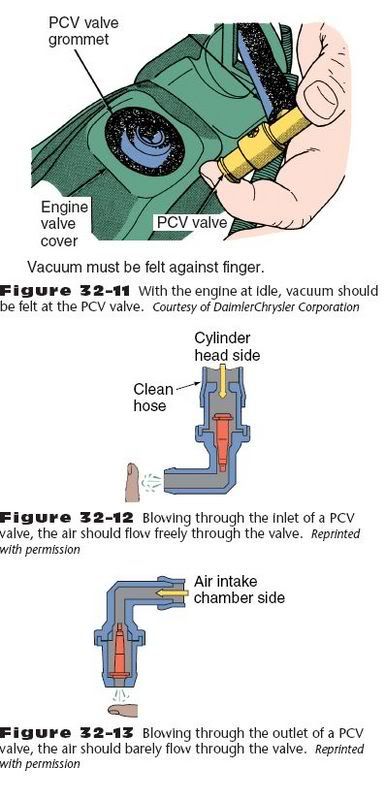

Functional Checks of the PCV System

A rough-idling engine can signal a number of PCV problems,

such as a clogged valve or a plugged hose. But before

beginning the functional checks, double check the

PCV valve part number to make certain the correct valve

is installed. If the correct valve is being used, continue by

disconnecting the PCV valve from the valve cover, intake

manifold, or hose. Start the engine and let it run at idle.

If the PCV valve is not clogged, a hissing is heard as air

passes through the valve. Place a finger over the end of

the valve to check for vacuum (Figure 32–11).

If there is little or no vacuum at the valve, check for a plugged or restricted hose. Replace any plugged or deteriorated hoses. Turn off the engine and remove the PCV valve. Shake the valve and listen for the rattle of the check needle inside the valve. If the valve does not rattle, replace it.

Some vehicle manufacturers recommend that the valve be checked by removing it from the valve cover and hose. Connect a hose to the inlet side of the PCV valve,

and blow air through the valve with your mouth while

holding your finger near the valve outlet (Figure 32–12).

Air should pass freely through the valve. If air does not

pass freely through the valve, replace the valve. Move the

hose to the outlet side of the PCV valve and try to blow

back through the valve (Figure 32–13). It should be difficult

to blow air through the PCV valve in this direction.

When air passes easily through the valve, replace the

valve.

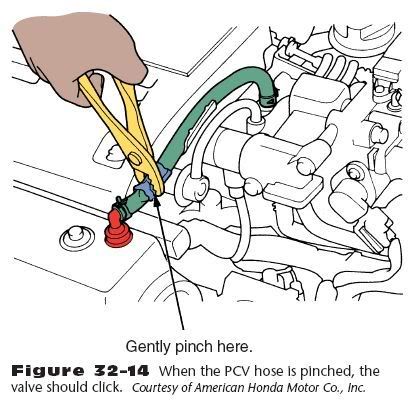

Another simple check of the PCV valve can be made

by pinching the hose between the valve and the intake

manifold (Figure 32–14) with the engine at idle.

You should hear a clicking sound from the valve when the

hose is pinched and unpinched. If no clicking sound is

heard, check the PCV valve grommet for cracks or damage.

If the grommet is all right, replace the PCV valve.

Remember that proper operation of the PCV system

depends on a sealed engine. The crankcase is sealed by

the dipstick, valve cover, gaskets, and sealed filler cap. If

oil sludging or dilution is found and the PCV system is

functioning properly, check the engine for oil leaks and

correct them to ensure that the PCV system can function

as intended. Also, be aware of the fact that an excessively

worn engine may have more blowby than the PCV system

can handle. If there are symptoms that indicate the

PCV system is plugged (oil in air cleaner, saturated

crankcase filter, and so forth) but no restrictions are

found, check the wear of the engine.

Edited by: VileZambonie  at: 3/11/07 10:18 am

at: 3/11/07 10:18 am

1

1